Key Points and Summary – Boeing’s “Bird of Prey”—often tagged YF-118G—was a 1990s stealth technology demonstrator that traded speed and weapons for learning.

-Built cheaply with a business-jet engine, mechanical controls, and big composite parts, it flew about 38 times to validate low-observable shaping, inlet concealment, edge alignment, and rapid-build techniques.

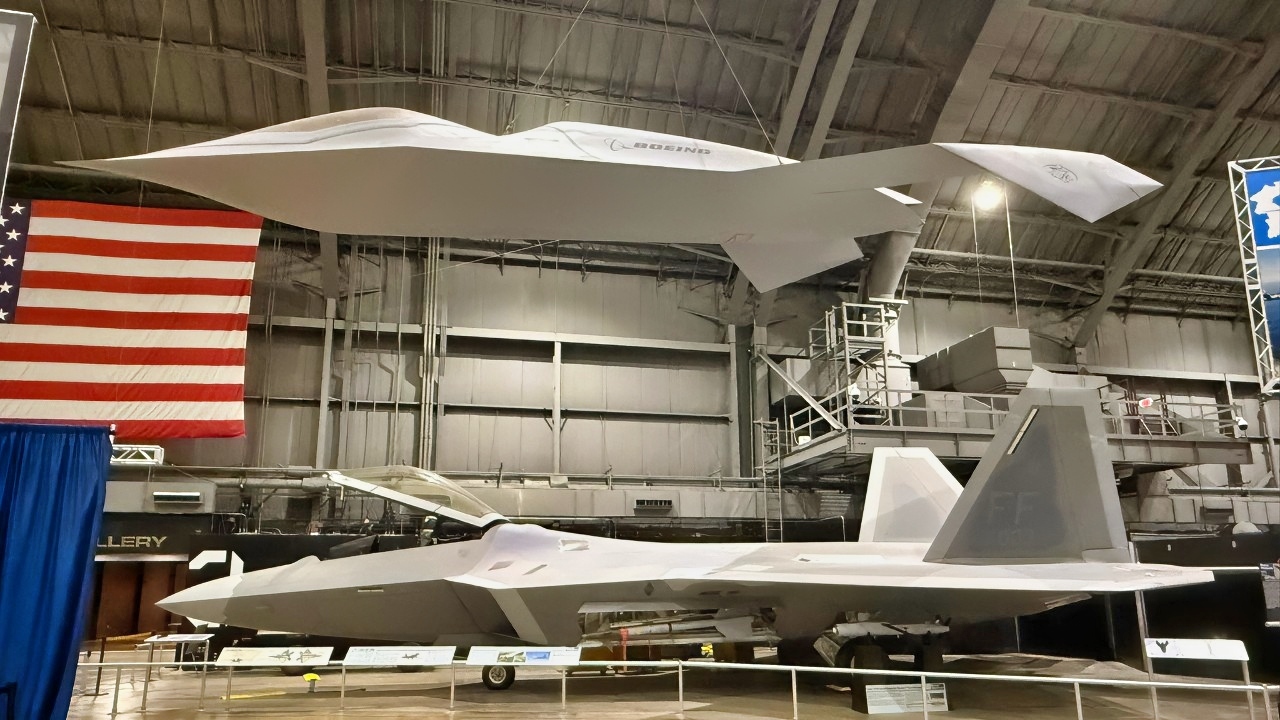

YF-118G Bird of Prey Hanging Above F-22. Image Credit: National Security Journal.

-The program’s modest envelope exposed real-world quirks—stability, gear-down drag, inlet distortion—that engineers fixed in flight test, proving methods that later became industry standard.

-It was never meant for production; its value was exporting lessons to later programs and normalizing affordable prototyping.

-The Bird’s real legacy is process: faster, cheaper ways to make stealth work.

-BONUS: We have included photos from our visit to see a YF-118G at the USAF Museum in Dayton, Ohio.

The YF-118G: I Actually Got Close to the Bird of Prey

On these pages, I frequently discuss my visit to the U.S. Air Force Museum, which took place on July 19-20 of this year.

And for good reason: I saw almost every boyhood fighter and bomber I worshipped.

When I was a kid, my family wasn’t exactly wealthy, so I spent a lot of time at the library poring over military magazines, Jane’s Fighting Ships books, which I could barely carry due to their massive size, and any other defense-related materials.

So, take it from me: I genuinely appreciate the history and significance of anything that flies or deploys for any military on Earth, and, in some respects, it is a significant part of my upbringing.

And while I was not exactly a kid when it flew (or rather, disclosed it had flown), the YF-118G made my jaw drop when I saw it back in Dayton this July. All I kept saying to myself: “Why isn’t this thing flying for someone’s air force?”

YF-118G USAF Museum. Image Credit: National Security Journal.

Well, come to find out, it was never meant to. That stings, but it’s true. Here’s the story of why.

A Tiny Stealth Fighter Experiment

The 1990s defense world was complicated. The Cold War had ended, budgets were tight, and the U.S. aerospace industry was consolidating at high speed. Lockheed had stolen the headlines with the F-117 and then the YF-22; Northrop had pushed B-2 technology into the open. McDonnell Douglas—soon to merge with Boeing—needed a way to show it could still shape the future, not just build for it.

Enter the “Bird of Prey.” Company leadership gave its advanced projects shop a simple, gutsy brief: demonstrate useful stealth and rapid-build techniques on the cheap. The goal wasn’t an operational airplane or a demonstrator that could be militarized with a wave of the hand. The aim was learning—to compress the painful, expensive, multi-year trial-and-error dance that stealth historically required. The team would try out ideas on a full scale, in the air, and discover which ones were gems and which were dead ends.

That’s why the program could stay small, fast, and relatively inexpensive. And that’s why the airplane looked the way it did: everything about it prioritized low observability and low cost of learning over raw performance.

YF-118G Bird of Prey. Image Credit: National Security Journal.

A Design That Put Stealth—and Affordability—First

Look at the Bird of Prey head-on (well, in my case, when I was at the Air Force Museum, it was straight up) and you immediately see what it was teaching.

The engine inlet sits high on the back, shielded by the canopy and an S-shaped duct so incoming radar can’t “see” the compressor face. The planform edges are ruthlessly aligned—canopy frame, wing breaks, gear doors—so radar energy reflects away rather than back.

The tailless layout with drooped wingtips eliminates the need for a vertical tail, which would serve as a radar billboard. Even the paint pattern was selected to reduce telltale shadows in daylight.

Under the skin, the airplane was just as deliberate. The team leaned into large, single-piece composite structures, disposable/low-cost tooling, and early digital design/virtual assembly techniques that would later be everywhere—from fighters to airliners.

The cockpit remained unpressurized and straightforward; the flight controls were mechanical/hydraulic, not fly-by-wire. On purpose.

When the mission is to explore shape, edge alignment, gaps, and manufacturing techniques, you reduce the number of variables and cut costs wherever possible.

The Boeing YF-118G “Bird of Prey” was a low-cost, 1990s experimental aircraft built at Area 51 that successfully tested advanced stealth concepts and manufacturing techniques later used in other programs. Image Credit: Boeing.

Cost discipline drove dozens of clever choices. The jet borrowed a Pratt & Whitney JT15D-5C—a reliable business-jet turbofan you’d expect to find on a Citation—so the team didn’t have to develop or integrate a bespoke powerplant.

Landing-gear components and other hardware were sourced from off-the-shelf suppliers. Even the cockpit clocks and environmental odds and ends were thrift-shop simple. In the most literal sense, the engineers diverted dollars from “nice-to-have” avionics into “need-to-know” stealth experiments.

Performance? Modest by design. Think roughly 260 knots and 20,000 feet as the practical envelope. But for measuring signatures, validating manufacturing methods, and evaluating handling of a tailless shape with novel control mixing, that envelope was enough.

What It Actually Did In The Air

The Bird of Prey first flew in the fall of 1996, then continued a compact flight program through 1999—about 38 sorties in total. That cadence—roughly a flight a month—tells you what kind of program this was. Engineers would fly, digest data, implement tweaks, and come back only when the next questions were worth risking another sortie.

Early flights revealed exactly the sort of issues you’d expect from a radically shaped, tailless one-off:

YF-118G Flying High July 2025. Image Credit: National Security Journal.

Gear-down drag and stability quirks forced changes to procedures and hardware fairings.

The unique outer-panel “rudderons” and inner-panel elevons needed revised mixing to tame yaw-roll coupling.

The dorsal inlet behaved differently at various throttle settings and angles, teaching hard lessons about inlet distortion and thrust loss in a compact S-duct.

This is the unglamorous magic of a testbed: you discover, fix, and document the realities that wind tunnels and simulations never fully capture. By mid-program, the team had refined the control laws, verified the basic envelope, and could focus on what the airplane was designed to do—low-observables work. The flights also validated the manufacturing bets—significant composite parts and virtual assembly—that would redefine how Boeing built cutting-edge airframes in the future.

Only three pilots ever flew the jet—one Air Force and two company test pilots—and their professional community later recognized the work with a prestigious test-pilot award. That nod matters: it tells you the airplane delivered real, not theoretical, insights.

“Cheap” In Black-Program Terms—and Why That Matters

The entire effort cost was on the order of $67 million—an astonishingly low figure for a stealth experimental aircraft. The number is worth lingering on because it illustrates the program’s philosophy:

Use a commercial engine and COTS hardware to avoid custom integration work.

Skip fly-by-wire and fancy avionics to focus on handling qualities and signature fundamentals.

Build it once with large composite pieces and disposable tooling; treat the airplane itself as the structural test article whenever possible.

Accept risk appropriate to a non-operational, envelope-limited test program.

By today’s standards, that money barely buys a complex test article’s wind-tunnel campaign, let alone a full-scale stealth demonstrator that flies dozens of times. The Bird of Prey proved you can buy learning, not just metal, if you constrain the problem intelligently.

Why The Program Ended—And Why That Was The Point

The Bird of Prey was never meant to grow into a frontline airplane. There were no hardpoints, no radar, no weapons bay, no mission systems, and no performance headroom. Once it answered the questions it was built to answer—from inlet concealment geometry and edge management to fit/finish techniques and materials processing—the value curve flattened. Continuing to fly a subsonic LO testbed solely to maintain operations would have been a better use of the budget, spent on addressing new questions.

By 1999, the team had gathered the necessary data. Within a few years, the industry and the Air Force publicly acknowledged the jet’s existence, precisely because its core techniques had become mainstream. That moment—rolling the airplane into the light—was itself a quiet victory lap: the Bird of Prey’s ideas had “graduated” into the open world of production and follow-on demonstrators.

“Could We Have Put It Into Production?” Here’s Why The Answer Was No

It’s tempting to look at any stealthy shape and imagine an operational variant with more thrust and a weapons bay. With the YF-118G Bird of Prey, that thought experiment collapses for several reasons:

Mission Fit: The configuration prioritized observability experiments, not combat flexibility. A viable fighter/strike platform requires a high volume of weapons, sensors, cooling, power, redundant systems, and carrier or expeditionary margins that the Bird never had room for.

Control & Stability: The tailless, drooped-tip layout created lateral-directional behaviors acceptable for slow, carefully scripted test sorties; however, it was not engineered for multirole maneuvering, high-G flight, or gust-loaded stability across a fleet’s worth of pilots and conditions.

Performance Ceiling: With its business-jet engine, the airframe’s aero and structural choices were never sized for supersonic dash, high-altitude persistence, or heavy bring-back weights. By the time you redesign for those, you don’t have a Bird of Prey anymore—you have a different airplane wearing a familiar paint job.

Certification and Survivability: An operational jet requires maintainability features, battle-damage tolerance, and system redundancy that would have necessitated a revision of the structure and weight budget. The Bird’s clever shortcuts—great for a testbed—become liabilities when lives and campaign tempo depend on the jet.

That “no” is not an attack. It’s a sign that the demonstrator did precisely what it should: de-risk the future and make the right things easier for the next designs.

What Carried Forward: The Real Payoff

If you’re looking for the Bird’s fingerprints, you won’t find a “Baby Bird” squadron patch. You’ll discover techniques and geometry choices echoed elsewhere:

Manufacturing & Digital Thread: Large composite subassemblies, low-cost tooling, and virtual reality/digital mock-up moved from exotic to everyday. Those methods shortened development cycles and cut rework on later programs.

Inlet/Exhaust Concealment: The dorsal, S-ducted intake and the emphasis on shielding line-of-sight to hot metal influenced how designers concealed propulsion hardware in subsequent stealthy UAVs and concept demonstrators.

Edge Management And Gaps: The Bird’s sawtooth edges, meticulous panel alignment, and flexible gap covers validated craftsmanship details that became the default in low-observable production lines.

Control Surface Philosophy: Mixing elevons and rudderons on a tailless planform—then untangling the coupling in flight test—fed a larger body of knowledge that later tailless UAVs and flying-wing concepts draw on routinely.

Affordability As A Requirement: Perhaps the most significant inheritance is cultural. The program proved that small, focused, company-funded demos can move the ball on stealth in a fraction of the time and cost of a government mega-program. That ethos remains alive in today’s rapid prototyping and flight demonstration efforts.

Why It Couldn’t Be “Scaled Up,” But Its Ideas Could

Could some of the Bird’s distinctive aesthetics—tailless silhouette, dorsal intake—have been scaled to an operational jet? Bits did. But the most transferable pieces were invisible: process, not posture.

The digital-to-factory pipeline previewed the industry’s “digital thread” ambitions—fewer surprises between the screen and the shop floor, faster changes, better fit.

Composite craftsmanship with giant single-piece skins taught the factory how to keep weight down while maintaining stealthy seams and edges.

Design-for-LO details—minimizing right-angle edges, hiding cavities, smoothing transitions—were stress-tested in real weather, with real fuel, by real maintainers and pilots. That practical feedback loop is priceless and hard to get from subscale models or static labs.

So no, the world was never going to see squadron lines of Bird-of-Prey-shaped fighters. However, many modern stealth airframes, both manned and unmanned, owe some of their remarkably reliable stealthiness to what this humble demonstrator taught.

The Decision To Stop: A Feature, Not A Bug

Another reason the YF-118G Bird of Prey belongs on the short list of innovative programs is that it knew when to end. The team resisted the classic temptations: bolting on a new sensor, chasing a new performance goal, or redesigning for an entirely different mission.

Instead, they captured the lessons, handed them to the programs that could use them, and parked the jet in a museum—proof of concept made tangible.

That’s how you keep technology vibrant across decades: prototype cheaply, fly just enough, harvest the insights, and move on. The Bird is a model for doing precisely that in the stealth domain.

Could We Have Used More Of Its Features Today?

It’s fair to ask: as threats multiply and timelines compress, should we be more aggressive about harvesting demonstrator DNA? In one sense, yes—we already are. The industry is again embracing small, quick demos to explore everything from novel inlets to sensor fusion and AI-enabled autonomy. The best of those efforts carry the Bird’s spirit: spend little, learn a lot, and let the right ideas flow forward without dragging along the rest of the airframe’s compromises.

But putting a Bird-like shape into production would still be the wrong lesson. Form follows mission. The Bird’s mission was learning, not fighting. Its legacy is strongest when its lessons—not its silhouette—show up in the next design.

A Quiet YF-118G Milestone, Hiding In Plain Sight

The YF-118G Bird of Prey’s public rollout years after it flew was an unusual moment of candor. The company and the Air Force essentially said: we’re revealing this because the ideas are no longer secrets—they’re standards.

That’s a rare kind of victory in the world of black airplanes. It means a shoestring project bent the curve for everyone who came after.

Today, the jet hangs above the floor at the National Museum of the U.S. Air Force in Dayton, and I loved every second I was there to see it back in July. You can see what I was talking about below.

Visitors drift under it on their way to celebrity airframes—the SR-71 nearby, the F-22 right below it—and many barely glance up.

That’s okay, well, it’s not, but whatever.

The Bird wasn’t built to steal the show. It was built to steal risk from the future.

YF-118G above and F-22 Raptor Below. Image from National Security Journal.

For a one-off that never carried a weapon, that’s quite an operational record.

And don’t worry, I am heading back to the museum in a few weeks when the government shutdown ends, and that’s the first plane I plan to pay homage to.

About the Author: Harry J. Kazianis

Harry J. Kazianis (@Grecianformula) is Editor-In-Chief and President of National Security Journal. He was the former Senior Director of National Security Affairs at the Center for the National Interest (CFTNI), a foreign policy think tank founded by Richard Nixon based in Washington, DC. Harry has over a decade of experience in think tanks and national security publishing. His ideas have been published in the NY Times, The Washington Post, The Wall Street Journal, CNN, and many other outlets worldwide. He has held positions at CSIS, the Heritage Foundation, the University of Nottingham, and several other institutions related to national security research and studies. He is the former Executive Editor of the National Interest and the Diplomat. He holds a Master’s degree focusing on international affairs from Harvard University.

More Military

Canada Is ‘Full Steam Ahead’ on F-35 Stealth Fighter

Why Does Turkey Have So Many Main Battle Tanks?

‘Cracked Barrels’: The U.S. Navy’s Big Railgun Failure Explained in Just 2 Sad Words

‘Had No Chance’: The Montana-Class Was the 71,000-Ton Battleship Destined to Fail

‘Captain, We Smacked It Another Submarine’: British and French Nuclear Missile Subs Collided

Richard Quinn

October 9, 2025 at 2:20 am

With a few squadrons on these in the Ukrainian Air Force, they could destroy all the Russian glide bombers. All they need do is intercept.